|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ROMAN | JAPANESE | MEDIEVAL | MISCELLANEOUS | AVAILABLE | CONTACT US | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

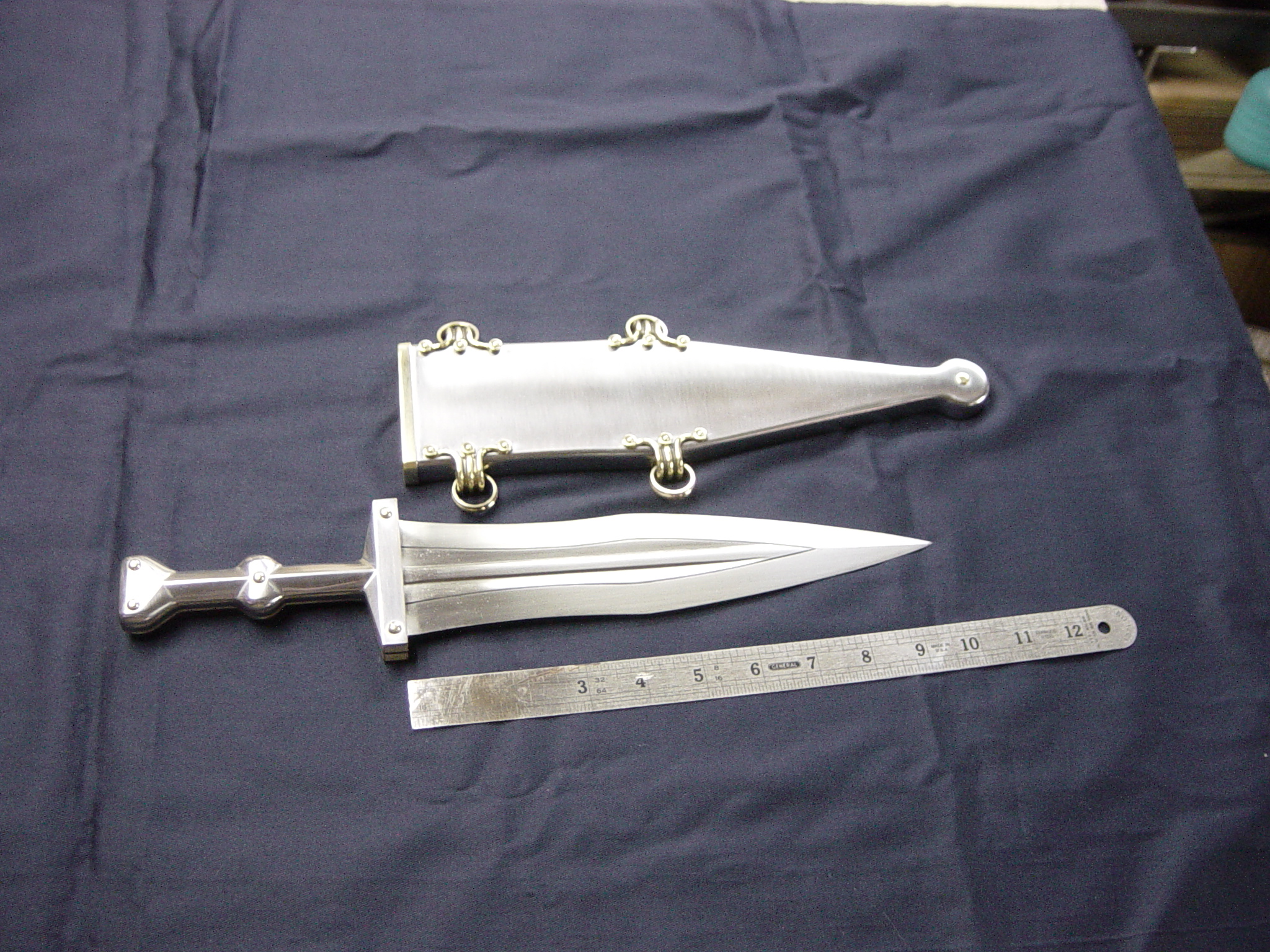

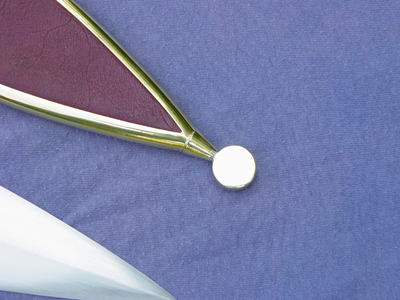

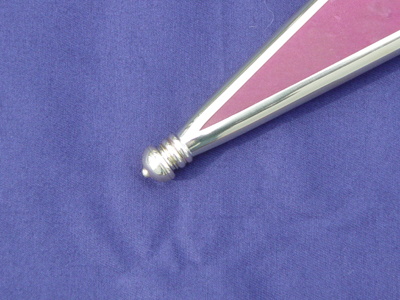

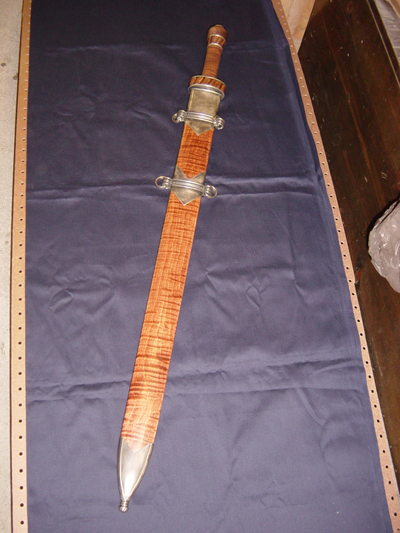

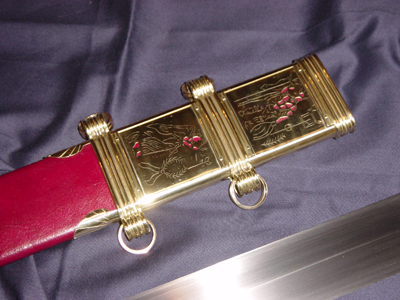

Roman All the Roman sword blades and spear heads are made from 5160 tool steel. All styles of blades and spears are done in a western style forge heated with coal that comes from South Arkansas. Depending on the style and size of the sword, the blades begin from a bar of 5160 tool steel that is oversized by as much as 1/4" depth and 2 and 3/4" width along with the correct length for the blade. The outline of the blade is then drawn out (forged to shape) whether it is a Mainz, Pompeii, Gladeius or Hisspaniensis style. The blades are then forged further in order to shape the edges and the tangs. Once this is done, the blades are ground to size and checked for flaws and balance. If no flaws are found and the balance passes inspection the blades are then annealed, tempered and finished. They are either sharpened or left blunt for re-enactment. Mark then adds his signature. The finished blades are then shipped to the customer. If a customer wishes to have the sword completed by Mark, then he will custom make the handle before shipping the completed artwork out. Note that these blades are made to be used in a combat style and are guaranteed to stand up to any use within reason. Most orders are shipped in 2 or 4 months depending on the work load. Spear tips. These are also made from 5160 tool steel. The price includes the entire length as the sockets can be a time consuming process. With the Pila or Pilum styles, Mark will make the socket and blade styles any length or socket size. All are hand forged from 1018 hot roll bar stock. The cost of $10.00 for butt caps made from 16 gage sheet steel. All are guaranteed under normal parameters of use. Sockets will be made to the specifications of the customer. All are heat treated giving them the strength to punch holes in any weight of armor. Note that if you have a piece that you wish custom made: it can be made. Roman era shield bosses. On the shield bosses Mark makes three styles. The outside dimensions have to be specified by the customer. Complete riveted style pilums with ash wood and any length of pirimidcal block or tip.

(Click on image to enlarge)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Created and Hosted by KHGraphicSolutions.com | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||